Busca Más Rápido y Mejor! Aktuelle Preise für Produkte vergleichen! Heute bestellen, versandkostenfrei. A piezoelectric sensor is a device that uses the piezoelectric effect to measure changes in pressure, acceleration, temperature, strain, or force by converting them to an electrical charge.

They are the most sensitive strain gauge technologies offering stable and repeatable accurate electrical output. Piezoelectric sensors do not require any power to continuously monitor an environment. Piezo sensors are ideal in anti-tamper and industrial health monitoring applications. Our bonding and packaging processes greatly improve the. Some are more accurate, convenient and useful than others.

Se hela listan på reprap. The aim was to devise a z-probe which was: 1. Is permanently mounted for convenience and improved reproducibility. Is low cost Most of these aims are self-explanatory but the advantage of using the nozzle as a probe should be explained: 1. Having no probe offset from the nozzle.

To cut a hole in the center of the piezo disc through which the filament within a PTFE guide tube (or Bowden tube) passes. When the hotend is pushed upwards by contact of the nozzle with the buildplate the piezo disc bends. At sufficient rate of bend a potentially large voltage can be produced. This is the signal.

Since piezo discs vary and designs for mounts to hold them vary, the degree of bend caused by a nozzle contact and the subsequent voltage generated varies. Since piezo discs used as sensors generate a larger voltage (and therefore clearer signal) when bent more, the housing holding the disc should only support the disc around its circumference. Since they are very sensitive there is some leeway in how much of the disc is supported by the upper part, and how narrow the top of the clamp can be. The piezo disc will still generate a signal even if pre-loaded.

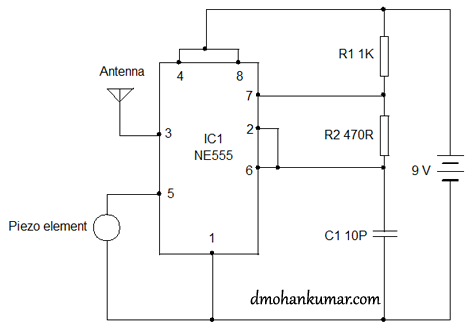

It is quite acceptable to tighten the machine screws holding the clamp to the upper part, to a reasonable degree to achieve a firm assembly with very little lateral. The signal conditioning circuit is in two parts, a differentiator and a comparator. The differentiator converts the rate of change of the piezo voltage into a voltage, that is to say, the faster the piezo voltage changes, the higher the output voltage of the differentiator. The comparator compares the output of the differentiator to a threshold voltage, set by VR2.

VRsets the input impedance of the differentiator, a higher resistance on VRgives a higher voltage spike for the same contact strength, higher spike in the same amount of time means a faster rate of change, gives a higher voltage output from the differentiator. Moving the printer from a very hot place to a. Most firmware will interact with the probe and its SCB as a digital switch. Some can interpret the output of the SCB as an analogue signal, so can be tuned slightly more precisely. In most firmware the probe will be configured as a z_min_endstop or wired to a dedicated z_probe connector.

If you setup the SCB to give a rising signal on triggered (active high) then the probe logic needs to be reversed in each case below. Please be aware with all of this configuration information it is unlikely to work by merely copying these settings and an understanding of how your firmware uses the information the probe provides will be required for smooth operation and fast, reliable, tuned performance. In general, two such slices are use with an electrode inserted in between. The entire structure is enclosed in a housing. A piezo-cera mic sensor plate transforms dynamic pressure fluctuations into electrical signals, which can then be processed accordingly.

The pressure fluctuation is generated by a seismic mass coupled to the piezo-ceramic part, which applies force to the piezo-ceramic disc when the entire system is accelerated. Get it as soon as We Dec 9. A simple resistor should get the voltage down to ADC levels. Can also be used for impact sensing or a flexible switch. Schau Dir Angebote von -piezo auf eBay an.

Riesenauswahl an Markenqualität. Folge Deiner Leidenschaft bei eBay! Ultrasonic Sensor Click here to read our ultrasonic sensor case study.

A customer needed a highly accurate and dependable ultrasonic sensor for use in a steam trap testing tool. Sensors detect changes in the environment and convert them into electrical energy. A piezoelectric sensor senses mechanical changes in the outside world and translates them into an electrical signal, which is monitored to measure those changes. External piezo sensors for multiple yarn insertions. Every Piezo Sensor can also be used as a Piezo Actuator.

The industrially most important piezoelectric materials consist of ferroelectric polycrystalline ceramics. These piezoelectric materials possess a Perowskit crystalline structure. Because they produce such high voltages, large resistors are often used to “load down” the piezo sensor in vibration-sensing applications. Piezoelektrische Sensoren arbeiten mit dem piezoelektrischen Effekt und haben sich als universelles Instrument zum Messen verschiedener Prozesse erwiesen. Sie werden für die Bestimmung von Druck , Beschleunigung , Spannung , Kraft oder als Gassensor in der Qualitäts- sowie in der Prozesskontrolle eingesetzt.

Sortiment med piezo-högtalare och mikrofoner Ca st. Ca stycken osorterade piezo-högtalare och mikrofoner i olika storlekar.

Inga kommentarer:

Skicka en kommentar

Obs! Endast bloggmedlemmar kan kommentera.